835 × 680 mm

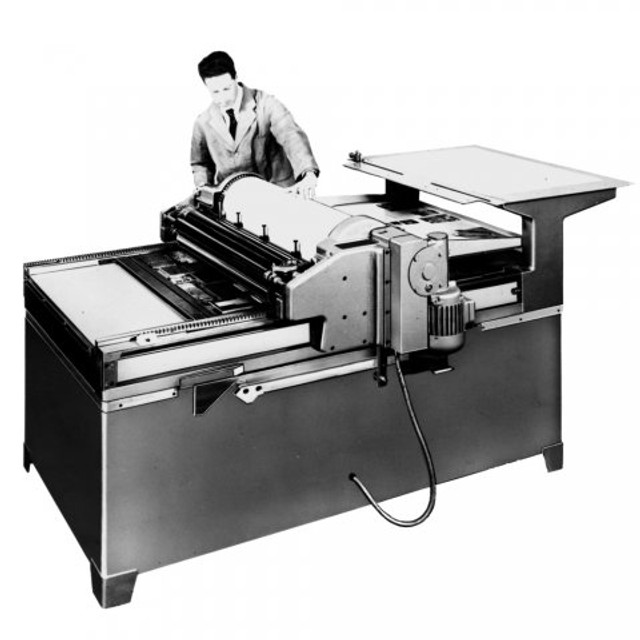

FAG Control 835

‹The newly designed proof and test press with same gripper and print line as the production presses of similar size. A machine which allows proofing and testing of formes and plates und working conditions, in particular — printing strength, print line and ink coverage. The ideal proof press for any printing plant, photo-engraver and platemaker. ›Quotation sheet, late 1950ies.

Moving production from Singen to Avenches

This press has been manufactured in Singen, Germany until 1962. Then they switched the production manufactury from Singen to the brand new manufactury in Avenches, Switzerland in 1962. Only after 2 years of manufacturing the FAG Contol 835 in Avenches, they developed it in to the slightly bigger FAG Control 839.

Quickspecs

Pressbed size

Paper size

835 × 680 mm

Form size

825 × 640 mm

Press size (l/w/h)

2.5 × 1.5 × 1.2 m

Press weight

1700kg

Standard equipment

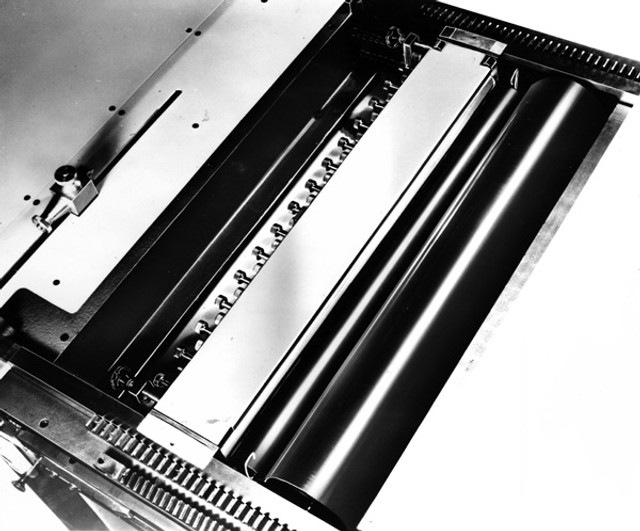

ME / Two speed power driven inking system with ink drum. Normal speed for printing. Acceleration for ink distribution and wash-up.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

Optional equipment

AFR / Automatic frisket.

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

DAS / Split steel rider unit for 2 colour work.

ES / Ink Duct with distributor

FRS / Register Punch. To be used with Register Plate Base RFP to punch holes of accurate dimensions on colour plates and facilitate positioning on base.

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

RFP / Register Plate Base, normal height 21.6mm. For close register proofing of origninal plates. Micro screw and spring lays allow movement of unit with fixed plates, for dot in register.

TC / Centre side lay for 2 colour work

TRM / Additional side-lay on the left. Adjusting device on the control panel.