384 × 540 mm

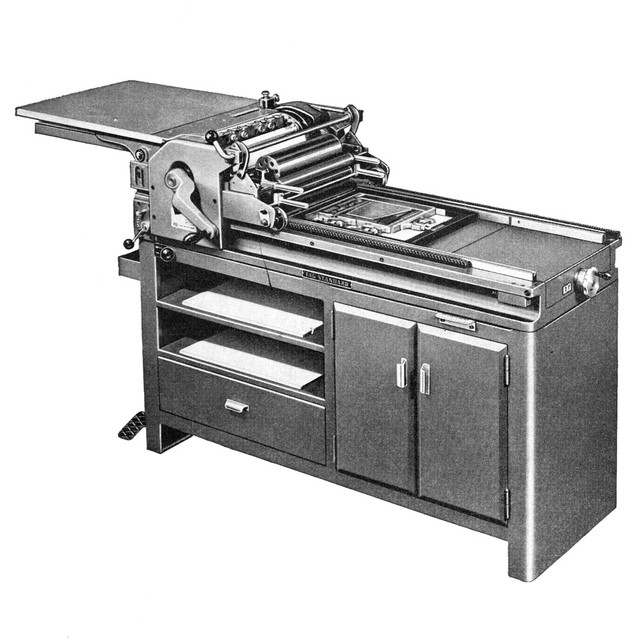

FAG Standard 550

‹With its robust construction and precision engineering the FAG Standard 550 allows perfect printing from any printing elements – thanks to the guaranteed minute adjustable bed in .0005"› FAG Standard catalog, early 1950ies.

Standard 550 vs. 510

The FAG Standard Models 510 and 550 vary only in the adjustable bed that came with the Standard 550. All models TP, AP, CP, RP and LP would exist as a Standard 510 and also as a Standard 550. Also all of these models could be optional equipped with a power driven cylinder! (To get more informatina about the models TP, AP, CP , Rp and LP see FAG Standard 510)

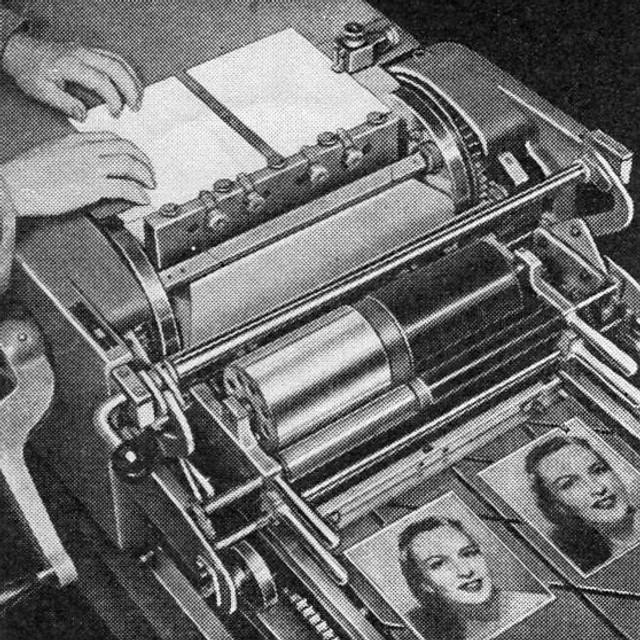

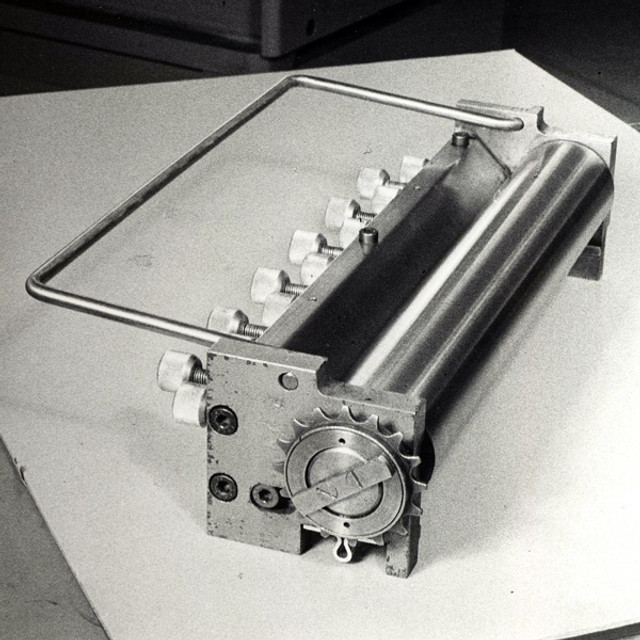

The inking system with that early clutch system (pretty similar to the Vandercooks No 4) has been modified in several steps during the years.

Quickspecs

Pressbed size

Paper size

370 × 530 mm

Form size

375 × 500 mm

Press size (l/w/h)

2.1 × 0.9 × 1.1 m

Press weight

Hand cranked: 640kg Power driven: 700kg

Standard equipment

ME / Two speed power driven inking system with ink drum. Normal speed for printing. Acceleration for ink distribution and wash-up.

MR / Micro adjustable bed movement with clock indicating accurate height in fractions of thousands of an inch. Height is measured directly off table.

Optional equipment

AFR / Automatic frisket.

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

DAS / Split steel rider unit for 2 colour work.

ES / Ink Duct with distributor

FRS / Register Punch. To be used with Register Plate Base RFP to punch holes of accurate dimensions on colour plates and facilitate positioning on base.

HFF / Swing-out hand frisket frame for proofing originals with dead metal attached.

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

MC / Cylinder drive with motor and FIXED SPEED SETTING.

PLA / VAK / Vacuum base with possibility to use up to 8 section for vacuum concentration. Especially for thin Nyloprint and Dycril plates. Vacuum pump capacity 60m3/h with all necessary parts for connection to PLA vacuum base.

RFP / Register Plate Base, normal height 21.6mm. For close register proofing of origninal plates. Micro screw and spring lays allow movement of unit with fixed plates, for dot in register.

SR / Precision chase

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

TC / Centre side lay for 2 colour work

Built in factory

Singen, Germany

First / last press delivered

1946–1962

Price range

12'550–20'000CHF (~1960)