900 × 680 mm

FAG Control 900

‹Production Presses with only tested formes ready to print. This is the goal you want to reach. In this case you certainly need a Test and Revision Press with the best possible printing strength and register. (…) The Testpress FAG Control 900 has been thoroughly checked by printers under the most difficult conditions, and the results achieved were excellent on all points. › FAG Product Catalog, around 1968

The FAG Control 900 was the biggest letterpress proofpress FAG ever built. Its antecessors were the FAG Control 800, FAG Control 835 and the FAG Control 839 (As with all models, the number means the width of the pressbed) which were slightly smaller models. With every revised version FAG sized this press a bit up until in 1968 they built the Control 900 for the first time.

Heavyweight proofpress

For its size, the FAG Control 900 only came with power driven cylinder and only with a fixed pressbed. Another very important difference to the smaller models was that with the FAG Control 900 will print in landscape format – means that the grippers will hold the sheet on the longer (!) side.

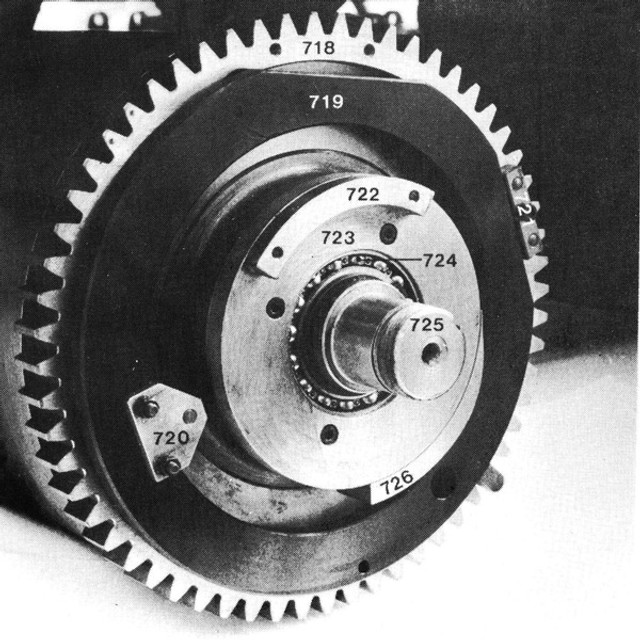

This press was not only the biggest letterpress proofpress FAG ever built, but also the heaviest. The heavy machine bed (about 1'000kg) with the underside stress is designed to guarantee maximum printing strength. This bed, together with the heavy closed printing cylinder (about 500kg) and full length axle which will not deflect under the heaviest pressure, form an association of lasting accuracy and precision.

Quickspecs

Pressbed size

Paper size

895 × 680 mm

Form size

894 × 640 mm

Press size (l/w/h)

2.45 × 1.6 × 1.2 m

Press weight

2000kg

Standard equipment

LAR / Automatic wash up device incorporated in special drawer, lever operated ductor blade.

MVA / Cylinder drive with motor, STEPLESS SPEED ADJUSTMENT. Automatic cylinder return with time adjuster for sheet delivery.

SSL / Quick action lock up bar, to block mounted plates and composition on machine bed.

Optional equipment

BAT / Special pitch line bars to suit all machine chases.

BRO / Cylinder sheet brush, adjustable, clears cylinder automatically as grippers pass to release sheet.

ES / Ink Duct with distributor

PLA / VAK / Vacuum base with possibility to use up to 8 section for vacuum concentration. Especially for thin Nyloprint and Dycril plates. Vacuum pump capacity 60m3/h with all necessary parts for connection to PLA vacuum base.

SAF / PMA / Automatic sheet delivery combined with pre lay device for automatic feeding of sheets. Automatic gripper opening at the feed board.

SAM / Safety device for motor-driven machine.

TRM / Additional side-lay on the left. Adjusting device on the control panel.

Number of presses built

70–80

Serial numbers

05.xx.xxx

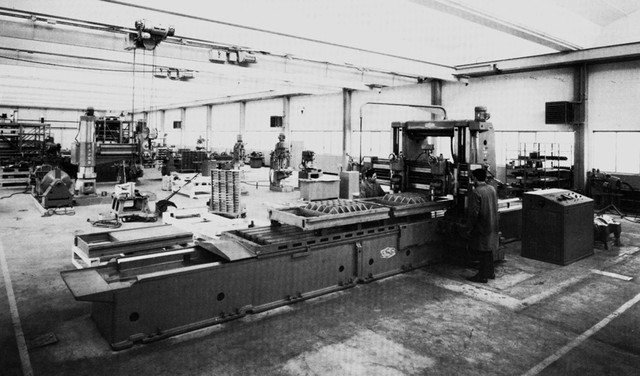

Built in factory

Avenches, CH

First / last press delivered

1968 / 1986

Price range

33'000 – 55'000CHF (~1968)

Known presses still in use